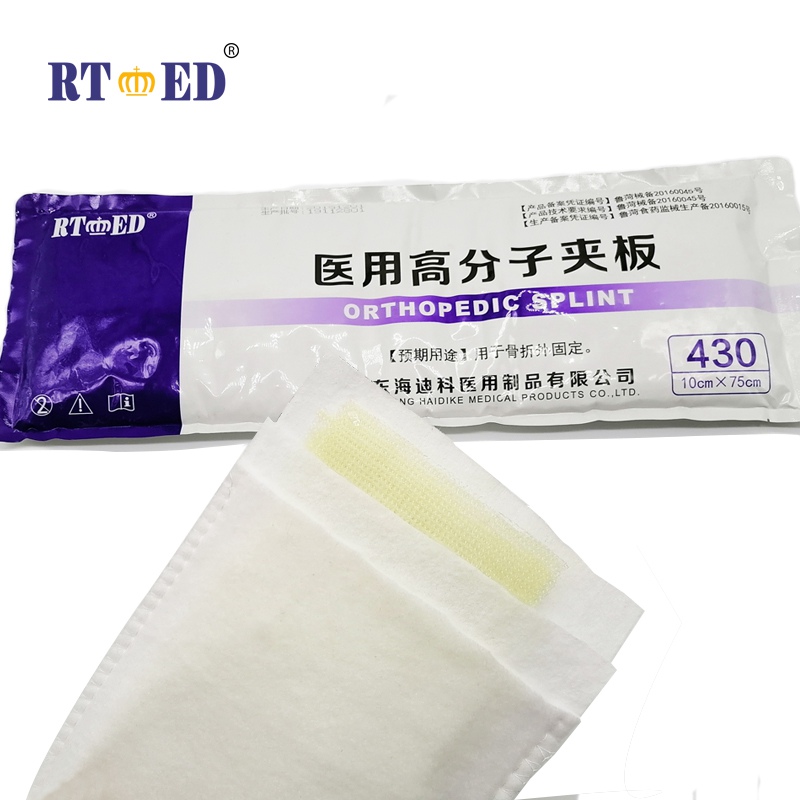

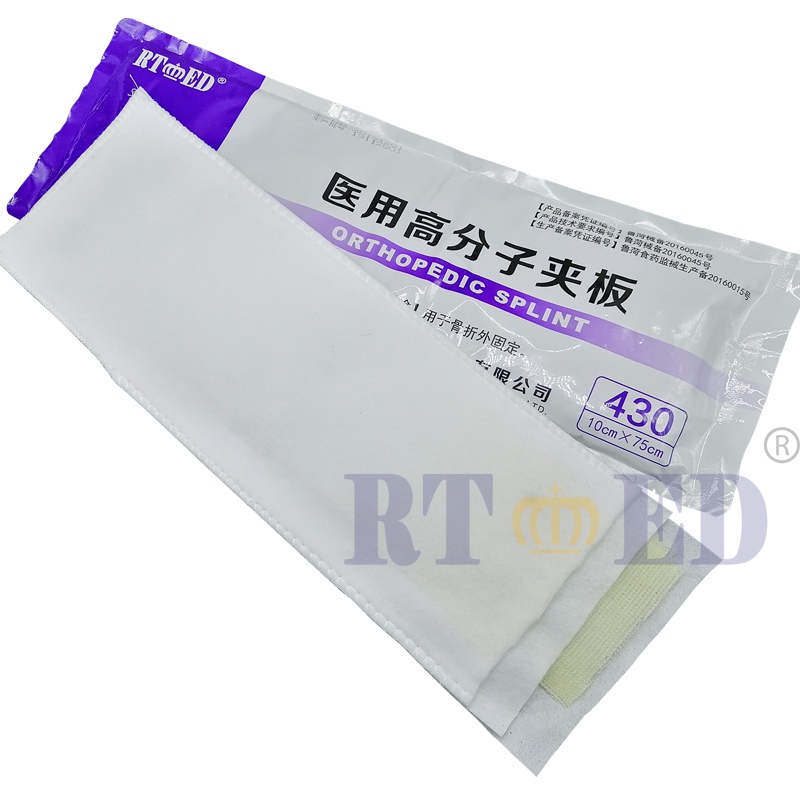

The medical polymer splint is made up of a multilayer fiberglass woven fabric impregnated with a wet solidified polyurethane and wrapped in a protective layer made of nonwoven fabric.

It is mainly used for plastic surgery, Department of orthopedics fixation, orthopedic, limb correction, supporting and protecting bone and soft tissue, and is suitable for emergency fixation, fracture and sprain, ligament injury and other temporary fixation. Various specifications of medical polymer splints can meet the fixed needs of all parts of the limb.

The Advantages Of High Polymer Splint Products

1. The specifications of medical polymer splint which are used conveniently and quickly are basically satisfied with the needs of limbs immobilization. After opening the package, it can be used directly, making fixed operation convenient and fast.

2. Comfortable, safe, hygienic and soft non-woven outer lining adhered to the skin, and the patient's comfort increased. The two layer of non-woven fabric was treated by special antibacterial treatment, effectively inhibiting bacteria and preventing the infection of wound site.

3. The strength of high strength, breathable and waterproof polymer splint is 20 times higher than that of plaster splint. The higher strength can effectively support the fixed parts and prevent the injured limbs from being injured again, which is conducive to their rehabilitation. The Yai medical polymer splint has the breathability of the general knitted fabric, and the patient wears comfortably. And the sub clean medical polymer splint adopts advanced breathable nonwovens, which enhances the permeability of medical polymer splint. The medical polymer splint will not crack and deform when it meets water. The patient can wear a bath and proper activity.

4. Excellent physical and chemical properties of X ray transmission rate of 100%, convenient for recovery; non-toxic, non irritating, aromatic smell.

5. Curing time is suitable for 5~8 minutes of curing time, so that doctors can have sufficient time to shape the shape.

The Method Of Using Polymer Splint:

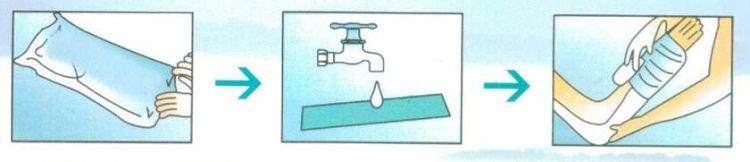

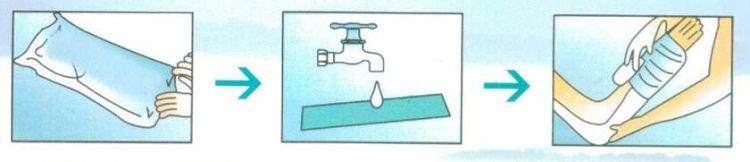

1. According to the different parts of the selection of different specifications of the product.

2. Open the package, take out the splint, put the blue mesh face on the side and soak it, and try to avoid the other side of the white non-woven fabric (the patient's skin contact surface) to soak in order to avoid the patient feeling wet and uncomfortable.

3. Cover the splints in a fixed position with a gauze bandage or a stretch bandage.

Specification For Polymer Splint Produced By Shandong Haidike:

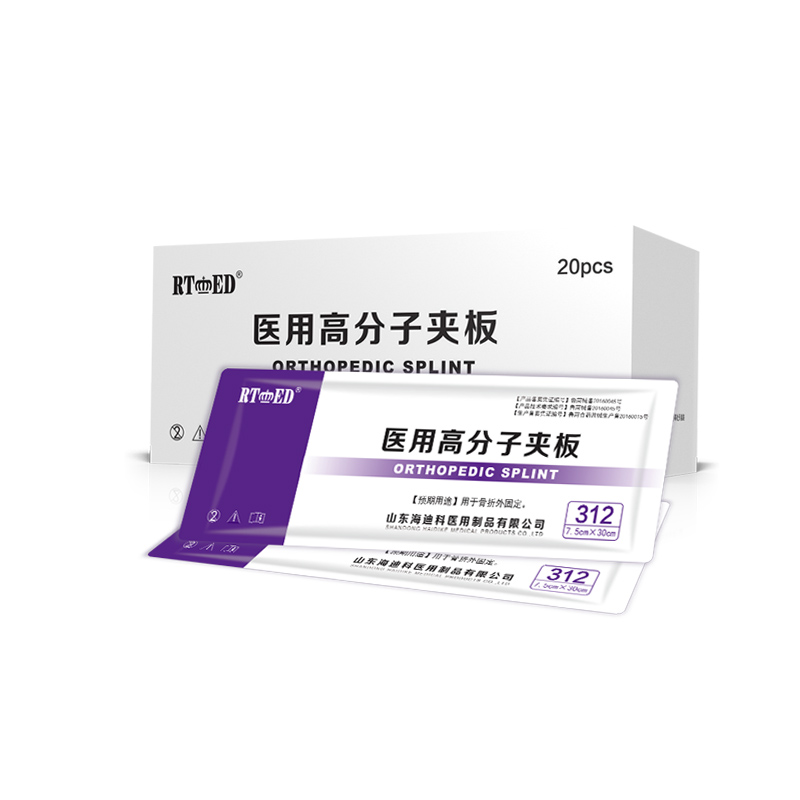

Product type | Model | Spec(Width * length) | Packing | Used part |

Polymer splint | 312 | 7.50cm×30cm | 50/ box | Wrists / children |

Polymer splint | 335 | 7.5cm×90cm | 20/ box | Upper limbs / lower limbs |

Polymer splint | 415 | 10cm×40cm | 30/ box | Upper limbs / lower limbs |

Polymer splint | 430 | 10cm×75cm | 20/ box | Lower limbs |

Polymer splint | 530 | 12.5cm×75cm | 20/ box | Lower limbs |

Polymer splint | 545 | 12.5cm×115cm | 15/ box | Lower limbs |

Polymer splint | 630 | 15cm×75cm | 20/ box | Lower limbs |

Polymer splint | 645 | 15cm×115cm | 15/ box | Lower limbs |